have questions?

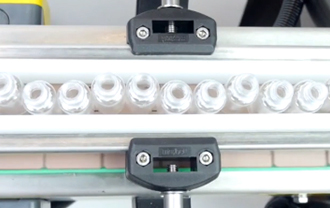

THC Tsunami can apply up to 2 labels and can be equipped with a volumetric pump by flow meter or position. Can perform a quick product changeover with no cleaning required. Increased Efficiency, Consistency, and Reduced Waste. Dosing volumes from 1ml up to 32oz (1L).

*PERISTALTIC AND PISTON PUMP OR FLOWMETER

*QUICK PRODUCT CHANGEOVER.

Increased Efficiency An automatic tincture filling and labeling machine can significantly increase production efficiency. These machines can fill and label tincture bottles quickly and accurately, reducing the need for manual labor and increasing production speed. |

Consistency An automatic tincture filling and labeling machine can ensure consistent dosages and labeling, which is essential for products requiring precise dosing. This consistency can help businesses avoid errors and ensure their products meet regulatory requirements. |

Reduced Waste An automatic tincture filling and labeling machine can minimize waste by accurately measuring and dispensing products, reducing the risk of overfilling or underfilling bottles. This can help businesses save money and increase their bottom line. |

Improved Safety An automatic tincture filling and labeling machine can help improve safety by reducing the risk of spills or accidents. These machines are designed to handle liquids safely and efficiently, reducing the risk of injury or damage to equipment.

|

Click our Shipping and Return page for detail information.